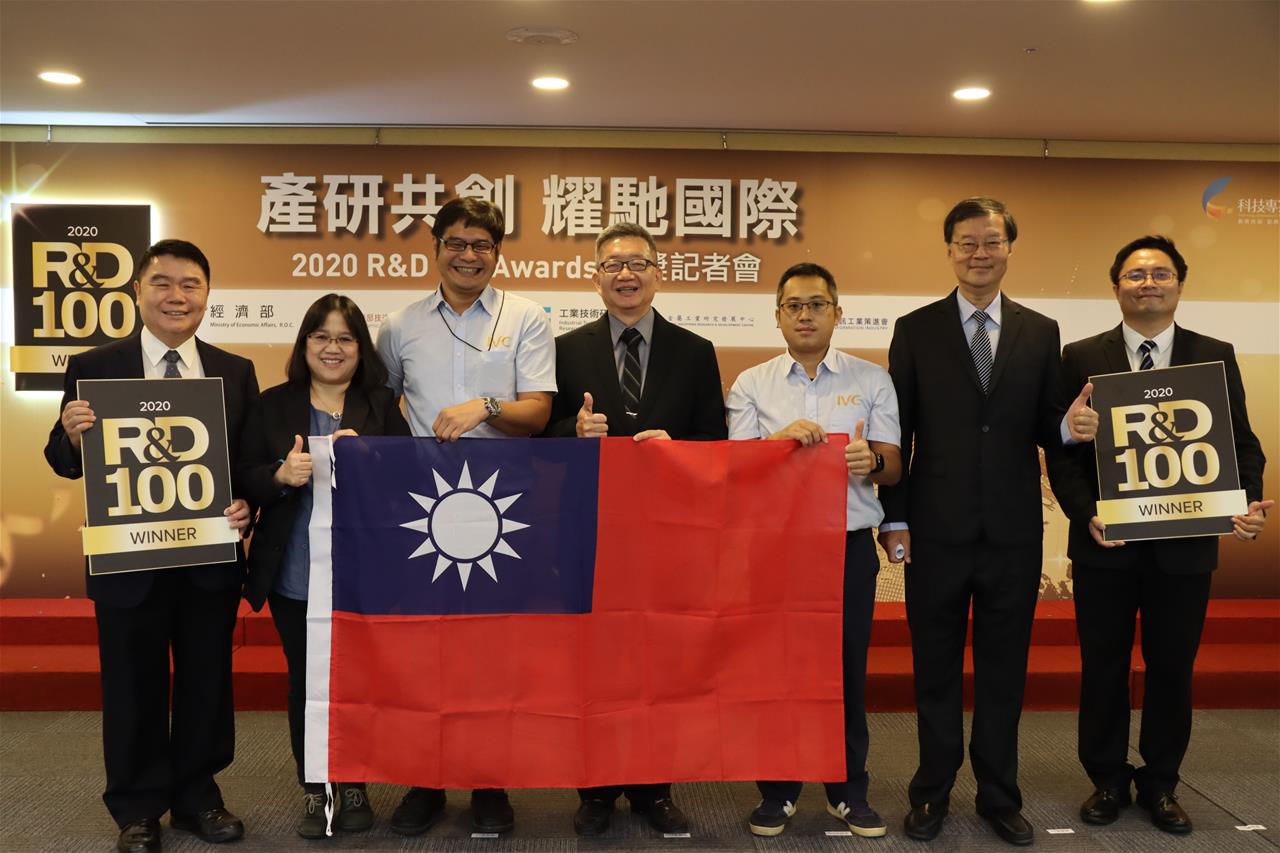

Known as the Oscars of the technology industry, the R&D 100 Awards searches the world’s most well-known industrial, academic, research sectors each year and locates the creative technologies that are capable of changing the world and creating a better future. The Metal Industries Research and Development Centre (MIRDC), standing out among thousands of competitors worldwide, wins two major awards this year and joins the ranks of renowned international institutions such as the MIT Lincoln Laboratory and Toyota Central R&D Labs., Inc. In addition to solidifying Taiwan’s core capabilities in industrial development and innovative strength, MIRDC’s achievements also reinforce the status and image of Taiwan’s industry and technology on the international stage.

Dr. Chiu-Feng Lin, the president of MIRDC, states that one of the winning technologies is “Continuously Rotating Wind Turbine UAV Inspection System”. Without shutting down wind turbines, it takes 5 minutes to complete the inspection of a single blade and even with 4 mm small cracks can also be detected. This technology saves more than 40% of the wind turbine inspection cost. In addition, the technology allows a group flight inspection mode to operate a large-scale wind farm inspection at the same time; therefore, the overall inspection efficiency of wind farms can be elevated.

The other award-winning technology is “Controllable Hydro-Reactive Magnesium Alloy”, which can be applied to agricultural technology, daily health, and healthcare industry. In terms of agricultural technology applications, by reacting magnesium alloy with water, the system can create hydrogen and nutrients such as magnesium, zinc, and calcium required for plant growth within a specific period. Hydrogen changes the physiological hormone response of the plant and improves their resistances to unfavorable conditions, which can grow better. As for the development of medical devices, the system is applicable to implants, such as bone screws, hemostatic forceps, vertebral columns or cardiovascular stents, the system facilitates the even and gradual degradation of the implants in tissue or bone regeneration and repair, until they are completely absorbed by the body. This eliminates the need of having to undergo surgery to remove the implants, which reduces pain of patients. Electro Chemical Machining System Technology developed by MIRDC is also nominated in the R&D 100 Awards. Although this technology did not receive an award, it has been successfully applied in the manufacturing certification of aerospace turbine engine diffusers, replacing the traditional use of mechanical and electrical discharge machining in complex structures with materials that are difficult to process.

With the support of the Ministry of Economic Affairs, MIRDC has solidified its R&D achievements under the Technology Development Program of the Department of Industrial Technology, facilitating the government in promoting industrial transformation and enhancing its R&D capability, also promoting the development and growth of next-generation industries in Taiwan. With the affirmation of the R&D 100 Awards, MIRDC will continue to exert the R&D achievements with the world, and highlight Taiwan’s presence on the international stage.