Step by step, the broad deployment and strategic adjustment of development for high-tech industries such as optoelectronics, semiconductors, biomedicine, energy, precision optics and micro-manufacturing have affected the orientation of Taiwan's overall economic activities and peripheral/satellite businesses. In critical industries making contributions to domestic economic development, the core processes and R&D steps have had to rely on foreign technology as a result of a domestic inability to supply customized equipment. This has resulted in a situation when manufacturers wish to enhance their competitive advantages and develop next-generation production applications, they instead remain limited and lose competitive opportunities.

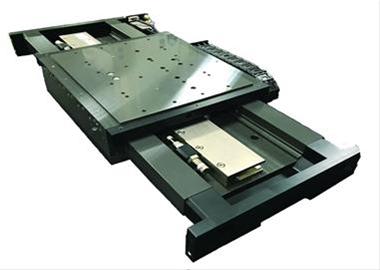

Faced with such harsh challenges in micro processes, the industry as a whole has had to invest greater resources and work hard on the development of new materials and new process technologies. Among the core processes mentioned above and in terms of testing equipment, the most fundamental, critical equipment module is the submicron and nanometer-scale precision air-bearing moving stage. To provide domestic industries with a solution, the Metal Industries Research and Development Centre (MIRDC) started in 2010 to invest in R&D for the DuoFloat aero static bearing technology. Experience has proven that its capabilities are comparable to those of major international manufacturers. The system has received 15 patents in the US, Taiwan and China. At the same time, built on the foundation provided by the DuoFloat aero static bearing, a submicron precision moving stage has now been developed that can be applied to 6-inch, 8-inch and 12-inch wafer processes. Current applications in the industry include: repair, testing, cutting, 3D ICs, micro LEDs, etc.

The MIRDC stated that this precision air-bearing moving stage indigenously developed by their team not only has zero friction, but also offers submicron positioning, repetition and linear precision. The moving stage's zero-abrasion capabilities allow it to guarantee even better that equipment precision and function are maintained at an optimal level, which lowers maintenance costs. It is hoped that the locally-manufactured, customized precision air-bearing moving stage, components, equipment provided and system development services provided by the MIRDC will resolve the bottlenecks that manufacturers are currently experiencing. Through a high degree of integration in critical processes, and relying on the submicron-precision positional control offered by such stages and structural designs, process equipment manufacturers' performance will be greatly enhanced.