With the popularization of circular economies, countries worldwide are committed to reducing their carbon footprint. Nonetheless, the global demand for aluminum continues to rise. To cope with limited resources and reduce carbon emissions, primary aluminum materials are gradually replaced by secondary aluminum materials which are estimated to grow 40% in the future. To achieve carbon neutrality by 2050, various countries have begun to impose a carbon border tax on products with substantial carbon footprints. In response, major international aluminum companies have successively launched low-carbon aluminum products using renewable energy (hydro/wind/solar) or secondary aluminum.

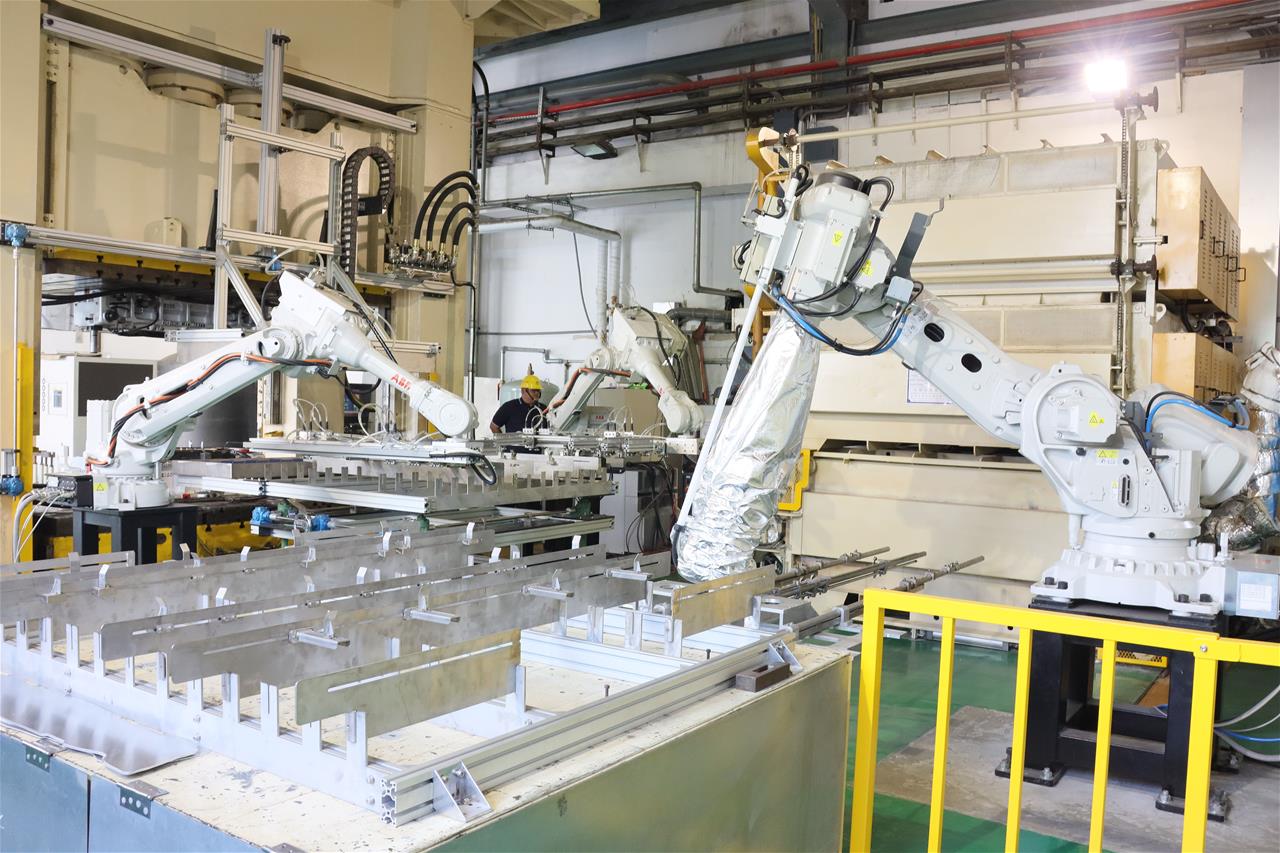

The current statistics indicate that the automotive industry will become the primary user of secondary aluminum materials by 2025 as demand for lightweight vehicles skyrockets. However, as aluminum alloy becomes stronger, aluminum forming will become increasingly complex, and the cold-stamping process predominantly adopted in Taiwan will gradually become obsolete. In this context, the Department of Industrial Technology, Ministry of Economic Affairs, has committed itself to conducting the development of secondary aluminum applications and technologies and promoting the development of a high-value and circular green industrial chain, commissioning China Steel Corporation (CSC) to launch a project, and Metal Industries Research & Development Centre (MIRDC) to provide processing technology R&D support, to develop warm/hot forming techniques and build Taiwan's first demonstration production line.

High-strength aluminum alloy becomes more formable after heating and softening. It also allows the alloy to be integrally formed into complex curved surfaces, such as anti-collision beams. Therefore, warm forming prevents sheets from becoming brittle and breaking also increasing dimensional accuracy, two significant issues in cold forming processes. Moreover, warm forming is suitable for the manufacturing of aerospace-grade aluminum (2xxx and 7 xxx). Combining warm forming and heat treatment can increase overall production efficiency by 50% and reduce waste generation by 60%, effectively promoting economic growth and environmental protection through technology.

Through numerical simulation and analysis, die design, and parameter development, MIRDC assists domestic vendors establish indigenous aluminum alloy R&D capabilities. By vertically integrating upstream material providers with downstream applied developers and peripheral equipment manufacturers, various sector are rallied together to develop warm/hot forming technologies for the manufacturing of high-strength aluminum alloy sheets for the aerospace, railway vehicles, and automotive, consequently enhancing industrial competitiveness, creating added value, and gaining international exposure in the process.